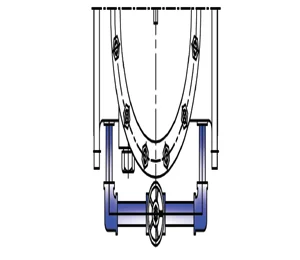

Counter Weight arrangement

Hydraulic Cylinder Arrangement

IBR Certified

NACE MR 0175 & MR 1030

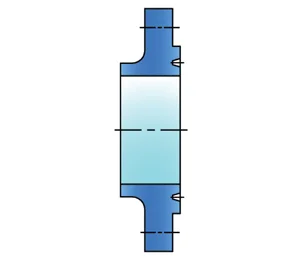

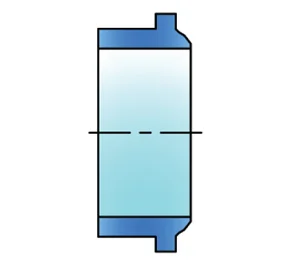

Lift type check valves will be supplied for the sizes for NPS < 2” Rest of the sizes are in swing type design.

Design and Manufacturing : BS 1868

Inspection and Testing : API 598, BSEN 12666 PART 1 & 2

End Flanges Dimension : ASME B 16.5(for NPS ≤ 24”) Series A & B (for NPS ≥ 24), MSS SP – 44 (for NPS ≥ 24)

BW End Dimension : ASME B 16.25

Face to Face & End to End Dimension : ASME 16.10, BS 2080

BW End Dimension : ASME B 16.25

Gasket Design : ASME B 16.20

Disk Design : Gravitational acceleration

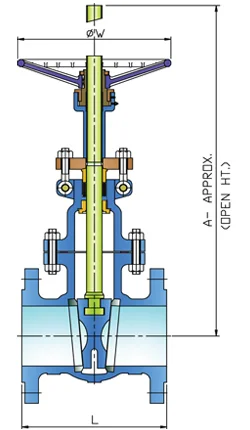

While not a valve in the traditional sense, check valves serve an important application namely to prevent flow in one direction while allowing it in the other. A check valve is self-actuated and designed to prevent fluid from flowing back into the system (prevent reverse flow). Real-life applications include preventing back flow into an injection line or into a pump. The fluid flow opens the valve by forcing a disk or ball in one direction. When the flow stops, the disk or ball is seated and closes the valve. They can be installed in horizontal or vertical upward flow piping.

Bodies and covers are high quality cast and afterwards precisely machined, directing the attention to prevent stress concentration. The design characteristic of check valves is the unobstructed passageway, with a full-opening when required.

The design of the body/cover gasket varies depending on the class of the valve. Class 150 to 600 check valves consist of a male-female connection with a graphite or spiral wound gasket. Class 900 and above check valves consist of a ring type joint. In pressure seal designs the sealing is achieved through a gasket that takes advantage of the internal pressure of the line. The material most commonly used is high purity graphite being located between the body and the body retainer ring.

| PART NAME | CARBON STEEL | ALLOY STEEL | STAINLESS STEEL | |

|---|---|---|---|---|

| Body | A 216 WCB / WCC | A 352 LCB / LLC | A 217 WC6 / WC9 / C5 / C12 | A 351 CF8 / CF8M / CF3 / CF3M / CF8C |

| Cover | A 216 WCB / WCC | A 352 LCB / LLC | A 217 WC6 / WC9 / C5 / C12 | A 351 CF8 / CF8M / CF3 / CF3M / CF8C |

| Seat Ring | A 216 WCB / WCC + 13% Cr./ A 217 CA 15 | A 351 C F8 | A 217 WC6 / WC9 / C5 / C12 + 13% Cr. / A 217 CA 15 | A 351 CF8 / CF8M / CF3 / CF3M / CF8C |

| Disc | A 216 WCB / WCC + 13% Cr. | A 351 C F8 | A 217 WC6 / WC9 / C5 / C12 + 13% Cr. | A 351 CF8 / CF8IWCF3 / CF3M / CF8C |

| Hinge | A 216 WCB / WCC | A 351 C F8 | A 217 WC6 /WC9 / C5 / C12 | A 351 CF8 / CF8M / CF3 / CF3M / CF8C |

| Hinge Pin | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A 276 TP 304 / 316 / 304L / 316L / 321 |

| Side Plug | A 276 TP SS 304 | A 276 TP SS 304 | A 276 TP SS 304 | A 276 TP 304 / 316 / 304L / 316L / 321 |

| Joint stud | A 193 B7 | A 320 L7 | A 193 B16 | A193 B77B8 |

| Joint stud nuts | A 194 2H | A 194 7 | A 194 7 | A 194 2H78 |

| Gasket | Spiral Wound SS316/316L/304L/321 with Grafoil filler | |||

| Disc nut | Stainless Steel | |||

Copyright © Jayant Valves

Powered by : #1 Vinayak InfoSoft - SEO Company Ahmedabad.