Gear Operation-applied force exceeds 350N

Limit Switch Arrangement

Electrical & Pneumatic Arrangement

Lantern ring arrangement for Vacuum service

IBR Certified

NACE MR 0175 & MR 0103

Position indicator

Locking Arrangement

Extended Stem

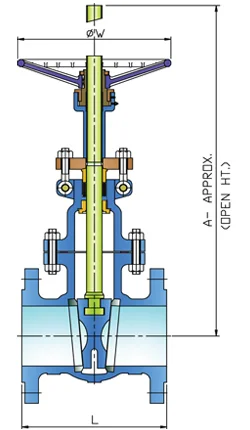

Design and Manufacturing : API 600 / ISO 10434 (2” ≤ 24”) BS 1414 / ASME B 16.34 (For NPS ≥ 24) & API 602 / ISO 15761 (For NPS < 2)

Inspection and Testing : API 598, BSEN 12266 Part – 1 & 2 MSS – SP – 61

End Flanges Dimension : ASME B 16.5 (For NPS ≤ 24”), ASME B 16.47 Series

A & B (For NPS ≥ 24), MSS SP – 44 ( For ≥ 24)

BW End Dimension : ASME B 16.25

Face to Face & End to End Dimension : ASME B 16.10, BS 2080

Gasket Design : ASME 16.20

Wedge Design : Solid Wedge for NPS < 2" & Flexible for 2” ≥ NPS

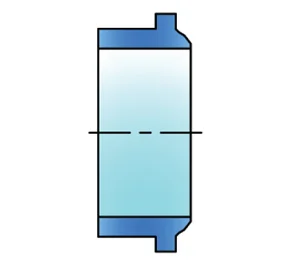

Gate Valves serve as efficient on-off valves with flow in either direction. In such a design, a wedge slides cross a general passage way in order to control fluid flow (like a sliding gate – hence, the name).

One of the most significant characteristics of this type of valves is its straight-through, unobstructed passageway when set in the “full open” position. This is made possible by the wedge lifting entirely out of the passage way. As a result, gate valves are characterized by a minimum of turbulence and pressure drop in operation.

While gate valves are good for applications requiring these two factors, they are not recommended for installations in which throttling would be a function. They are designed for on/off service

Bodies and bonnets are high quality cast and afterwards precisely machined, directing the attention to prevent stress concentration. The bodies of gate valves consist of a straight through port that guarantees minimal turbulence and resistance to flow. In both designs, bolted bonnet and pressure seal, the bodies consist of guide slots to accommodate the wedge during opening or closing of the valve. Bonnets are made either of one piece only –the yoke then being an integral part of it or have two pieces, depending on the size of the valve. This ensures the perfect alignment with the body what leads to an accurate opening and closing.

All Jayant Gate and Globe Valves have backseat threaded in the bonnet, or for the pressure seal valves, welded to the bonnet. Into pressure seal the hard facing is stellite 6 or equivalent.

The stems of Jayant Gate Valves are forged from one piece and ACME threaded, then mechanized and finally provided with a smooth finishing in order to minimize friction. In gate valves, the union of stem and wedge shall be in T form, designed to prevent the stem disengaging itself from the wedge while being in service. This design includes a conical raised surface that presses the seat against the bonnet backseat in the fully open position.

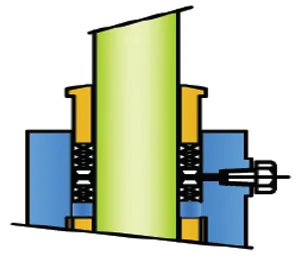

The design of the body-bonnet/gaskets varies depending on the class of the valve. Class 150 gate valves consist of a square joint in 2″ and an oval one for all other sizes. Depending on the valve service it can be supplied flat-face gasket with graphite or PTFE. Class 300 and 600 valves consist of a circular spiral wound gasket. Class 900 and above gate valves consist of a ring type joint. In pressure seal designs the sealing is achieved through a gasket that takes advantage of the internal pressure of the line. The material most commonly used is high-purity graphite being located between the body and the body retainer ring.

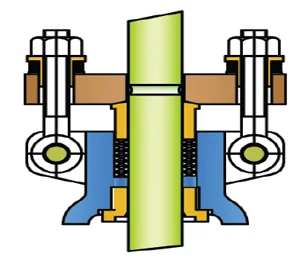

All Jayant gate valves 2″and above valves feature a flexible wedge unless otherwise specified by the customer. The flexible wedge shifts along the body of the valve during opening and closing, being held in position by a guide slot that minimizes the friction between body seat and wedge. This design is specially suited to compensate slight thermal deformations produced by the pipe or the valve itself safeguarding a better sealing between body and wedge seats.

| PART NAME | CARBON STEEL | ALLOY STEEL | STAINLESS STEEL | |

|---|---|---|---|---|

| Body | A216 WCB/WCC | A 352 LCB /LLC | A 217 WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Bonnet | A216WCB/WCC | A 352 LCB /LLC | A217WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Seat Ring | A216WCB/WCC+13%Cr. | A 351 CF8 | A 217 WC6/WC9/C5/C12 /A 217 CA 15 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Wedge | A216WCB+13%Cr. Facing | A 351 CF8 | A 217 WC6/WC9/C5/C12+13% Cr. | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Stem | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A 276 TP 304/316/304L/31617321 |

| Gland Flange | A105/CS/A216WCB | A105/CS | A105/CS | A1053/CS3/A351 CF8/CF8M/CF3 |

| Back Seat | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A 276 TP 304/316/304L/316L/321 |

| Gland | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A276 TP 304 / 316 / 304L /316 L /321 |

| Joint Sutd | A 193 B7 | A 320 L7 | A 193 B16 | A 193 B73/B8 |

| Joint Stud Nuts | A 194 2H | A 194 7 | A194 7 | A194 2HV8 |

| Gland Stud | A 193 B7 | A 320 L7 | A 193 B16 | A 193 B77B8 |

| Gland Stud nuts | A 194 2H | A 194 7 | A194 7 | A194 2HV8 |

| Gasket | Spiral Wounded ss 316/3161 /304I 321 with Grafoil filter | |||

| Stem Packing | Braided Graphite and Die Formed Graphite ring | |||

| Yoke Sleeve | SG Iron / A439 Gr.D2 / Bronze | |||

| Hand wheel | Below 2″= Malleable lorn & Above 2″ SG Iron / Fabricated Steel | |||

Copyright © Jayant Valves

Powered by : #1 Vinayak InfoSoft - SEO Company Ahmedabad.